Jump to: navigation, search

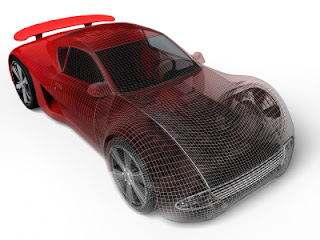

Class A surfaces is a term used in automotive design to describe a set of free form surfaces of high efficiency and quality. Although, strictly, it is nothing more than saying the surfaces have curvature and tang ency alignment - to ideal aesthetically reflection quality, many people interpret class A surfaces to have G2 (or even G3) curvature continuity to one another (see free form surface modelling).

Class A surfaces is a term used in automotive design to describe a set of free form surfaces of high efficiency and quality. Although, strictly, it is nothing more than saying the surfaces have curvature and tang ency alignment - to ideal aesthetically reflection quality, many people interpret class A surfaces to have G2 (or even G3) curvature continuity to one another (see free form surface modelling).

Class A surfacing is done using

computer-aided industrial design applications. Class A surface modellers

are also called "digital sculptors" in the industry. Industrial

Designers develop their design styling through the A surface, the

physical surface the end user can feel, touch, see etc.

A common method of working is to start

with a prototype model and produce smooth mathematical Class A surfaces

to describe the products outer body. From this the production of tools

and inspection of finished parts can be carried out. Class A surfacing

complements the prototype modelling stage by reducing time and

increasing control over design iterations.

A class A surface can be defined as any surface that has styling intent.